Article contributed by Brittni Peterson, PhD, and Emily Wozniak, PhD

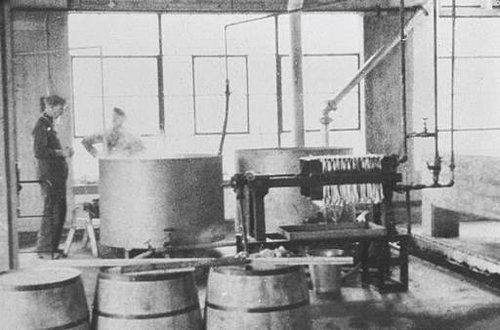

Adopting new technologies is a challenge in heavily regulated environments, as innovation is often stymied in favor of safer, established technologies. This is especially true of the biomanufacturing industry. Mainstream bioreactors have been improved only incrementally since the original fermenters that produced ingredients like citric acid in the 1920s (Pictured, left) or yeast in the 1930s and 40s (de Becze and Leibmann, 1944).

Modern-day stirred tank bioreactors have certainly benefited from incremental innovations like rotating mechanical impellers, automated monitoring and control of the culture environment, and single-use technology. Modern versions still operate on the same principles, and share many of the same restrictions as the original designs. These systems work very well for certain types of products, like proteins created from bacteria, or proteins that are easily expressed from mammalian culture, such as unmodified human IgGs.

But traditional biomanufacturing methods are not ideal for the fastest growing applications in the industry.

More complex biologic therapies, like fusion proteins, can be difficult to produce in stirred tank environments (read more here and in BPI). In addition, these methods are not cost-effective for small batches, such as those needed for early-stage clinical trials (read more here and in GEN).

But traditional biomanufacturing methods are not ideal for the fastest growing applications in the industry.

It’s clear that a different approach is needed for these applications. But it doesn’t have to be a new technology.

Here we discuss the development of perfusion bioreactors for biotherapeutic manufacturing over the past 50 years and why they are only recently being recognized as a viable alternative for the industry.

A SLOW START

In the 1970s and 1980s, perfusion bioreactors made their debut into the bioprocessing world to meet demands for a more “in vivo-like” cell culture environment. The goal was to explore novel culture techniques to overcome sub-optimal mammalian cell expression systems. Some of these perfusion technologies were successful in increasing cell densities and productivity in a smaller bioreactor, but early perfusion bioreactors were limited in their ability to meet manufacturing standards (Voisard, 2003). The perfusion systems were seen as unnecessarily complex by regulatory authorities because they were typically closed-loop to prevent contamination and in-process monitoring systems were not sufficiently advanced. Combined with the lack of sufficient analytical methods to confirm protein identity and quality, like peptide mapping, HCP analysis, and de novo sequencing, most users preferred the simpler stirred tank methods. Consequently, perfusion technology had questionable utility in the therapeutics space and was passed-over for the more established batch-fed options.

During this time, protein engineering, cell expression systems, and chemically defined media formulations vastly improved (Voisard, 2003). Batch processing technology also improved with advancements in agitation technology, fed-batch methodology, bioreactor design, sterilization techniques, and temperature control. Collectively, these innovations enabled production of higher titers by less optimal systems. Due to these advances, as well as the early limitations to perfusion technology, batch processing continued to be the dominant protein production method for biotherapeutics.

TIME FOR A CHANGE

Over the past 30+ years, perfusion technology has improved to match or exceed batch or fed-batch biomanufacturing for many product types and applications. What were once limitations of perfusion technology, such as long run lengths and the necessity for single-use systems, are now advantages (BioPlan Associates). Single-use systems decrease contamination risks and overhead costs, while longer run lengths allow for continuous upstream manufacturing and more product harvested from a single run. Perfusion systems are making a comeback, with some experts predicting that this technology is the future of bioprocessing.

THE TECH: PERFUSION VERSUS BATCH AND FED-BATCH METHODS

Batch and Fed-Batch

In traditional batch manufacturing using stirred tank bioreactors, cells are cultured in media-filled tanks and product is harvested in a single large batch after 1-3 weeks. Fed-batch is a version of this process where new media and supplements are added periodically to provide the cell line with fresh nutrients.

However, neither the accumulated waste nor protein product is removed until the end of the culture period, which creates an inconsistent environment that can result in several problems:

1) The impeller agitation can lead to stratification and create microenvironments in which inconsistent nutrient delivery and build-up of waste products (e.g., lactic acid and ammonia) can lead to poor cell health. This can result in variable product quality in the tank.

2) Agitation caused by impeller rotation, sparging (bubbling a gas through the culture for cellular respiration), and exposure to gas-liquid interfaces (Thomas and Geer, 2011) can cause shear stress (movement of fluid across a solid boundary, like the outside of a cell or against a folded protein). Shear stress is a well-documented issue in biomanufacturing that influences both cell health and protein quality (Nesta et al., 2017). Shear stress is especially concerning for product quality, since it may lead to expression of undesired proteins, variations in biological activities like post-translational modifications like glycosylation patterns (Senger and Karim, 2003; Goldman et al., 1998), or protein aggregation (Nesta et al., 2017).

3) Long residence time of the product with the cells can lead to a variety of negative outcomes including additional modification of the protein (Nesta et al., 2017), degradation of the product, and inhibition of protein expression.

Perfusion

In contrast, perfusion bioprocessing involves continuous feeding, clearing of waste products, and harvesting of protein product for up to several months at a time. For applications where a cell line is under-performing in fed-batch, this is a necessary advantage to achieve higher yields. Perfusion processes accomplish longer runs through constant removal of waste and delivery of nutrients to extend cell line viability and stability, resulting in a greater overall protein yield. Similarly, continuous harvest of sensitive proteins allows for immediate storage of the product, protecting it to create a more consistent, stable, and higher quality final product.

The Type: Perfusion adaptors versus perfusion solid-substrate bioreactors

Not all perfusion systems are equal. While there are several types of perfusion bioreactors, we will discuss two here: perfusion adaptors and solid-substrate bioreactors.

In standalone perfusion bioreactors (solid-substrate bioreactors) cells are retained in the bioreactor because they grow either within a convoluted solid matrix (packed bed bioreactors) or on one side of a semi-permeable membrane that acts like a filter (hollow fiber bioreactors). Here we will discuss hollow fiber bioreactors (HFBRs), in which cells and products are retained on one side of hollow fibers. Fresh media flows at a high rate through the opposite side, and nutrients diffuse across the semi-permeable membranes to feed the cells while waste products diffuse away from the cells across the membrane to be removed from the system (Figure 2).

Perfusion adaptors, on the other hand, are accessories meant to retrofit stirred tank bioreactors to function as perfusion systems. One of the more popular perfusion adaptors for tanks uses alternating tangential flow (ATF). ATF systems use a filter as a cell retention device. The ATF adaptor attaches to the tank so that the culture media flows through the hollow fibers with defined size-retention cutoffs. These filters retain the cells and allow waste and product to flow out of the tank. The cells and remaining media are then pushed back into the tank by the alternating current.

Both solid-substrate bioreactors, like the hollow fiber bioreactor, and perfusion adaptors, like the ATF system, solve many problems faced by batch and fed-batch production methods. They remove waste from the cell culture environment, continually harvest product, improve cell health to allow for longer runs, and they allow for production within a smaller footprint than large stirred tank systems. However, the ATF attachments have significant drawbacks that are solved by hollow fiber bioreactors.

1. Shear stress and filter fouling

ATF systems pull the media and cells from the tank into the adaptor, where a cell retention device keeps the cells within the system while the media containing product is harvested. The cells are then pushed back into the tank by the alternating current. The influence of this back-and-forth media flow on cell health and protein quality isn’t well understood, but it may increase the level of shear stress experienced by the cells and protein products (Wang et al., 2017). Despite advances in pump and filter design, tank adaptors like ATFs are also often prone to filter fouling or clogging of the cell retention device which can disrupt or prematurely terminate a run. While hollow fiber bioreactors use the hollow fibers to retain cells and cell products, the cells grow in a single space (thus are not pushed back and forth) where media flows at a slow rate.

2. Material Costs

With the introduction of automation in many bioreactor systems, materials have become one of the biggest cost drivers in a biomanufacturing run. ATF systems lead to higher protein total yields, but utilize more media than stirred tank bioreactors. During a run, media is perfused through the system at a rapid rate of 1-5 vessel volumes per day (VVD). Because the cells are suspended in a large vessel, ATF systems also require “bleeding”, or removal, of the cell culture and media up to 30% of the vessel volume to maintain cell density. Additionally, while the product may be continually harvested, the collected product is dilute and requires additional processing steps.

Because solid-substrate bioreactors grow cells in a smaller space, they inherently use less media than tank perfusion adaptors. In these systems, the cells grow to tissue-like densities, and thus do not require “bleeding” to maintain density. The protein is also harvested at a 10-20x higher concentration, reducing or eliminating downstream concentration steps to save both time and money. However, the ATF attachments have significant drawbacks that are solved by hollow fiber bioreactors.

THE TOP: CELL CULTURE COMPANY’S ACUSYST HOLLOW-FIBER PERFUSION SYSTEMS

Perfusion systems had a rocky start, but they’re quickly becoming the go-to for challenging molecules and small batch production. In particular, solid-substrate perfusion bioreactors come out on top compared to both stirred tank and tank perfusion attachment systems.

Cell Culture Company utilizes AcuSyst hollow fiber bioreactors to generate high yield, high-quality products in a fraction of the time at a fraction of the cost. How?

AcuSyst bioreactors are:

- Able to achieve tissue-like densities (2-5×10^8 cells/mL) in an optimal environment to maintain cell health and protein production for long periods.

- Automated to reduce operational complexity and costs while also maintaining batch-to-batch consistency.

- Linearly scalable with processes validated to a single hollow fiber cartridge to streamline process development, speed up timelines, and reduce costs.

- Fully closed and single use to reduce contamination risks, even over long runs.

- Small footprint to decrease facility and raw material costs, while also increasing throughput.

To learn more, read our articles and case studies in GEN and BPI magazine, or visit our website.

REFERENCES

Goldman, James, Rendall, Ison, Hoare, Bull. 1998. Monitoring recombinant human interferon-gamma N-glycosylation during perfused fluidized-bed and stirred-tank batch culture of CHO cells. Biotechnol Bioeng., 60:596-607.

Nesta, Nanda, He, Haas, Shpungin, Rusanov, Sweder, Brisbane. 2017. Aggregation from Shear Stress and Surface Interaction: Molecule-Specific or Universal Phenomenon? Bioprocess Intl., http://www.bioprocessintl.com/analytical/pre-formulation/aggregation-shear-stress-surface-interaction-molecule-specific-universal-phenomenon/.

Thomas and Geer. 2011. Effects of shear on proteins in solution. Biotechnol Lett., 33(3):443-456.

Senger and Karim. 2003. Effect of shear stress on intrinsic CHO culture state and glycosylation of recombinant tissue-type plasminogen activator protein. Biotechnol Prog, 19(4):1199-209.

Voisard, D. 2003. Potential of Cell Retention Techniques for Large-Scale High-Density Perfusion Culture of Suspended Mammalian Cells. Biotechnol. Bioeng. 82:751-765.

Wang, Godfrey, Ravikrishnan, Lin, Vogel, Coffman. 2017. Shear contributions to cell culture performance and product recovery in ATF and TFF perfusion systems. J Biotechnol., 20(246):52-60.